Did you know that the reliability of engineering marvels, from bridges to airplanes, hinges on a secret weapon? Brace yourself: load testing machines. This isn’t just engineering jargon; it’s the backbone of safety and durability.

Today, as construction projects scale to unprecedented heights, the role of these machines has taken center stage. Ignoring their significance could spell disaster for countless industries and every user involved. Discover why now, more than ever, you should care.

Shockingly, load testing machines have revolutionized how we perceive safety standards. These unsung heroes ensure that structural failures are prevented before any human ever sets foot on a construction site. But that’s not even the wildest part...

Beyond safety, these machines are redefining how industries approach innovation. From aerospace to civil engineering, they allow for ambitious designs that push boundaries while keeping risks firmly in check. But hold onto your seatbelt because what happens next will challenge everything you thought you knew about construction safety...

Experts were astonished when recent advancements showed that some load testing machines could predict structural weaknesses ahead of time using AI technology. What’s more, this breakthrough poses new questions about efficiency and long-term feasibility. What happens next shocked even the experts...

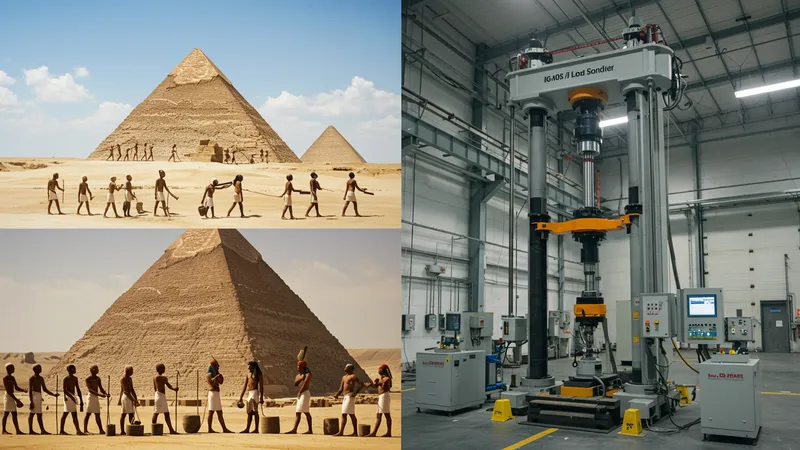

It may surprise some to learn that load testing machines have origins dating back to ancient civilizations. When the Egyptians built the pyramids, they used primitive versions of stress testing – understanding the importance of load-bearing long before modern technology. Fast forward to today, and the principles remain the same but with much more at stake in terms of human life and economic impact.

Even the most advanced machines today borrow key principles from these ancient methods. Studying these historical innovations can lend fascinating insight into the progression of load testing technology. But there's one more twist that takes this story full circle...

In the 19th century, the industrial revolution transformed the landscape of load testing. As factories burgeoned and infrastructure boomed, the need for precise and reliable testing methods soared. This revolution birthed the first machines that would lay the groundwork for today’s precision instruments. Yet the implications reach much further than mere manufacturing...

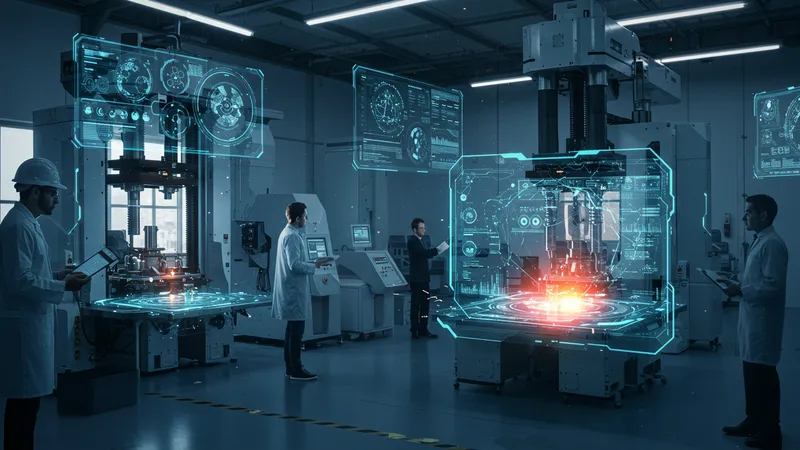

Contemporary machines now deploy artificial intelligence to simulate multiple scenarios, ensuring that engineers can foresee and mitigate risks. This not only showcases technological progression but also hints at even more transformative potentials. What you read next might change how you see this forever.

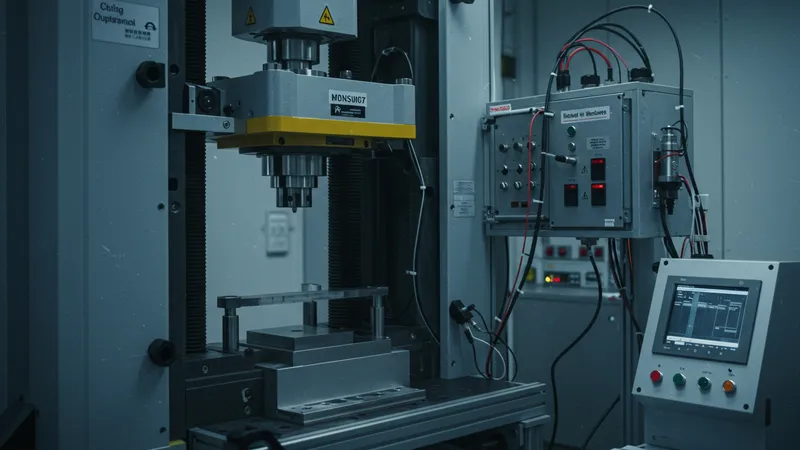

At first glance, a load testing machine might seem like just a heap of metal and wires. On closer inspection, it becomes apparent they are intricately designed to mimic real-world stresses on materials. A typical machine consists of hydraulic presses, sensors, and sophisticated feedback systems, allowing precise measurements and adjustments in real-time.

These machines handle diverse tests like tension, compression, and fatigue – each essential for evaluating different material properties. For instance, tension tests measure the force required to pull something apart, revealing its robustness. But how these machines adapt to various materials is where their true genius lies...

Customization is key. Each material and structure presents unique challenges, prompting developers to innovate devices tailored specifically for those needs. Unexpectedly, this adaptability underscores an unheard-of economic and safety advantage within industries, reducing waste and ensuring structures that are beautifully efficient yet inherently safe.

It's not just about steel and concrete; load testing machines are pivotal for advanced materials like composites used in future-mobilizing technologies. As these innovations march forward, so too does the demand for testing capabilities that keeps pace. The revelations that follow could redefine industry standards forever...

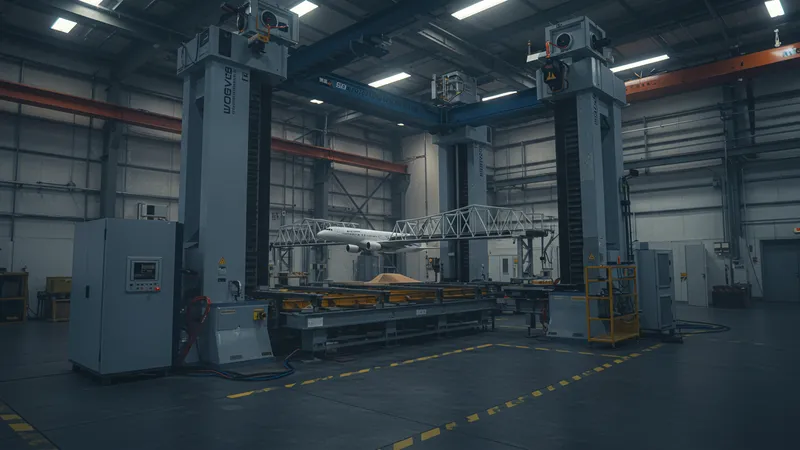

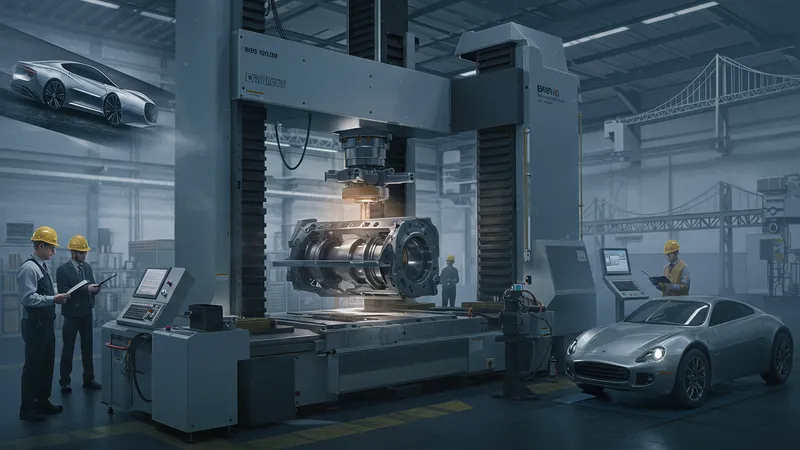

It's easy to think of load testing machines as the domain of niche industries, but they are critical across a vast spectrum. Be it the automotive industry assuring vehicle durability, or civil engineers safeguarding our public infrastructure, these machines are indispensable. They ensure that accommodations of stress are not theoretical but validated under controlled conditions.

Manufacturers rely on these machines to prevent costly product failures. Imagine a new bridge tested multiple times under simulated extreme conditions before ever bearing its first load of commuters. This proactive measure not only improves safety but also investment longevity – more than many might expect.

Driven by data, load testing supplies a wealth of information for continuous improvement. Small surprises in test outcomes can serve as early indicators of needed design tweaks, saving time and money in the long run. But how do these machines evolve with ever-changing demands? The answers might just be groundbreaking.

As industries harness the power of machine learning alongside load testing, the insights grow exponentially. These systems now self-optimize for enhanced predictive capabilities – a feat that offers tantalizing possibilities, raising questions about the future role of human intuition in load assessment.

Artificial intelligence emerges as a game-changer in the realm of load testing. Recent breakthroughs mean machines don't just test—they predict. This predictive capacity allows early detection of potential failures, equipping engineers with real-time insights that enable proactive interventions.

One fascinating development is the integration of Machine Learning algorithms that analyze vast datasets from previous tests to forecast unseen failure modes. It transcends past methodologies that solely scrutinized current testing outcomes. Now, machines learn from history to better anticipate future challenges.

Moreover, the integration of AI doesn't eliminate jobs; it opens doors for highly specialized roles that guide the programming of these intelligent systems. Engineers and data scientists unite in unprecedented ways, creating an ecosystem where human expertise and machine precision coalesce harmoniously.

But this raises an ethical quandary: how do we balance machine autonomy with human oversight? This complex dance between technological advancement and ethical constraints might just be the most profound transformation yet...

While load testing machines are certainly game-changing, they come with hidden costs that can derail even the most meticulous budget plans. From the initial investment to ongoing maintenance and updates, these machines demand more than just monetary resources.

Unexpectedly, electricity consumption represents a significant expense, further exacerbated by the operational requirements in running intense testing simulations. It's an often-overlooked factor that can impact not just budgets, but also environmental footprints.

Then there's downtime for repairs and calibration, which, if not managed correctly, could lead to production halts. Precision needs regular tweaks to maintain its edge, requiring specialized technicians who aren't always readily available. The labor costs add up, sometimes unexpectedly.

Yet, industries are learning to offset these costs through innovative strategies. By integrating energy-efficient practices and scheduled maintenance, they aim to mitigate these financial burdens. The evolving strategies to juggle expense and efficiency offer compelling lessons still to come...

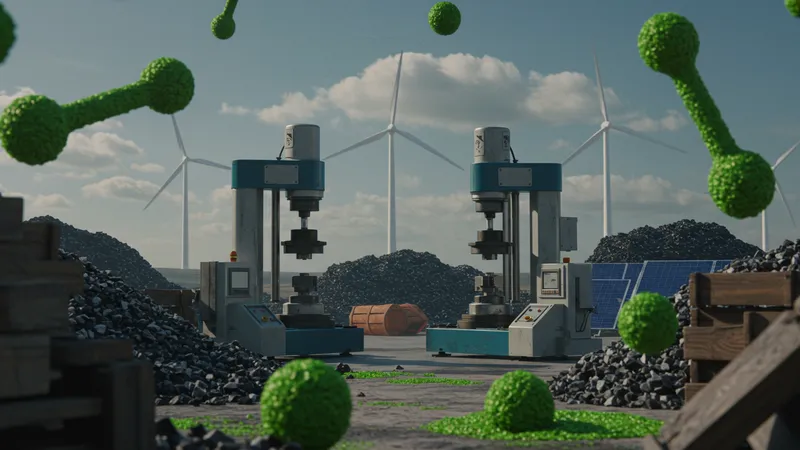

It's ironic, perhaps, that machines designed for structural safety have their own environmental impact. The sheer scale of resources consumed in both production and operational phases presents significant challenges to sustainable practices.

As demand soars, manufacturers face mounting pressure to address these concerns, investigating renewable energy sources and biodegradable materials for machine components. Load testing machines become a microcosm of sustainability challenges faced by the broader industrial sector.

The irony is not lost on industry leaders, who increasingly view these machines as both part of the problem and the solution. The path forward involves critical evaluations and judicious selection of testing methods to minimize eco-damage.

Yet, as with most industries grappling with sustainability, embracing renewable solutions presents potential revenue streams. Whether through tax incentives or green certifications, the balance between cost and environmental stewardship continues to evolve with surprising trade-offs.

The global market for load testing machines is anything but uniform. Divergences in regulations and standards create a patchwork that firms must navigate carefully. This disparity can influence everything from design decisions to pricing strategies.

Still, the competitive landscape is fierce, driving innovation at a breakneck pace. As demand for infrastructure expands globally, companies operating across borders must tailor their approaches to meet varied expectations and compliance mandates.

The fragmented regulatory scene often hinders progress, serving as both a gatekeeper and a disruptor. Innovators grapple with achieving uniformity in a market where rules can shift overnight, demanding agility and foresight.

However, these challenges can lead to unexpected collaborations, where enterprises join forces to standardize practices, easing market entry. It's these alliances that fuel optimism and potentially set new precedents in harmonizing disparate markets.

As we peer into the horizon of structural safety, there’s a paradigm shift driven by load testing machines. Their impact reaches beyond construction, fundamentally altering perceptions of risk across industries.

This influence extends to consumer confidence, as buyers increasingly demand assurances tied to rigorous and transparent testing results. The expectation for safety is not confined to engineers but trickles into public consciousness, reshaping customer expectations.

Technological evolution ensures that tomorrow's machines will possess unprecedented accuracy and intelligence—encouraging hope for safer urban environments. Yet, this progress does not come without its own set of ethical considerations involving data use and privacy.

The dilemma of reconciliation between innovation and privacy unveils broader debates about technological dependence. Still, the potential to revolutionize safety should not be underestimated, as the delicate balance between opportunity and apprehension is struck once more.

Amidst the excitement of machine capabilities lies an age-old question: can machines truly replace human intuition in load testing? While data provides empirical insights, intuition holds the key to interpreting nuances beyond code.

Historically, human insights have sparked groundbreaking advances, often seeing beyond what cold data suggests. Even as AI bolsters load machine testing, the human element remains indispensable—a pairing for the ages.

Nonetheless, machines offer consistency and precision that human evaluators can't always match. This juxtaposition provokes questions about the ideal equilibrium between human expertise and technological application.

Ultimately, the quest reveals a deeper narrative: our unending quest for harmony between technology and humanity. To achieve this equilibrium invites rigorous dialogue, continuous learning, and collective commitment to shared progress.

While safety rests front and center, the benefits of load testing machines extend far beyond. In unexpected ways, these machines contribute positively to innovation across sectors such as architecture and even medicine.

For architects, the data extracted from load tests inspires daring designs once deemed impractical. Similarly, in medicine, testing insights relate closely to biomechanics, influencing improved prosthetic designs and surgical simulations.

Such interdisciplinary applications illuminate the broader impacts of load test data, showcasing supporting evidence across a mosaic of fields. The expansion of this data’s relevance continues to unravel previously unseen benefits.

These ripple effects reaffirm the transformative power that inviting collaboration across disciplines unlocks. Yet, these possibilities still only scratch the surface of potential—what lies next could be even more astonishing...

Surprisingly, principles at the heart of load testing carry valuable lessons for daily life. The concept of pre-emptive stress testing resonates with how we navigate personal and professional uncertainties.

Considering scenarios ahead and prepping responses bolsters preparedness, reducing risk and fostering resilience. Load testing inadvertently becomes a metaphor for thoughtful planning in everyday decision-making.

Moreover, the adaptation to changing conditions underscores flexibility essential for success beyond engineering. It mirrors life’s unpredictable challenges where adaptability becomes a key ally.

Thus, while load testing fundamentals serve as engineering cornerstones, in broader terms, they offer frameworks for navigating life’s complexities with poise and foresight. How these paradigms translate into wider contexts remains ever more intruiging.

Load testing machines embody the bridge between theoretical premises and practical application. They assure that structural theories hold true under real-world conditions, reinforcing engineering principles through tangible evidence.

This correlation reflects in the balance between academic knowledge and technology-driven solutions—each necessary to the other’s success. Through load testing, the innate link between hypothesis and proof emerges stronger than before.

In practical terms, this fusion guides industry best practices, informing future academics while shaping current curricula to better prepare a workforce accustomed to balancing theory with execution.

The challenge lies in continuously nurturing this symbiosis, maintaining relevance amidst the rapid pace of technological progression. Yet, as disciplines advance in unison, we edge closer to a world grounded in evidence yet free to innovate.

Amid advancements, integrating ethics with load testing practices becomes critically essential. As machines wield power in predicting failures and guiding safety protocols, ethical considerations ensure their impact remains truly beneficial.

This responsibility extends to data sovereignty, privacy, and equitable access to technological enhancements. The assurance that innovations align ethically contributes to sustainable and responsible progression.

Yet, ethical dilemmas challenge stakeholders to consider fairness across a diverse array of applications, including access irrespective of geographic or economic limitations. This requires widespread commitment to shared ethical guidelines.

The onus lies on leaders across disciplines to guide this discourse, ensuring that load testing machinery develops alongside a steadfast moral compass. As technology advances, so too should the vigilance that equity remains intertwined with progress.

The future dazzles with the promise of ever-safer, more sustainable innovations led by load testing machines. Yet, they remind us that technology alone isn't panacea; human judgment, ethics, and collaboration guide their potential. To navigate tomorrow’s challenges, unity and diverse perspectives will be vital. Share this story, and bookmark the journey as we climb into this new era together—the ultimate fusion of technology and humanity.