Did you know that a single packaging machine choice could make or break a business? With advances in technology, the perfect machine offers more than just efficiency—it revolutionizes your entire production process!

In today's competitive market, smart packaging isn’t just an advantage; it’s a necessity. Understanding your packaging options can unlock opportunities for growth and cost savings that were previously unimaginable. The stakes have never been higher!

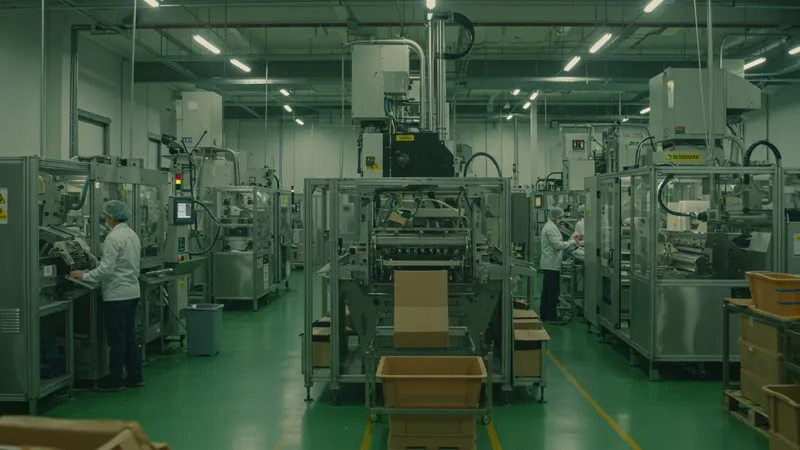

Many businesses rush into buying packaging machines without considering the hidden costs or the latest innovations. For instance, did you know that some packaging machines can be controlled remotely and require minimal human intervention? That’s a real timesaver.

But that’s not even the wildest part: some machines are equipped with AI capable of predicting maintenance needs before problems arise, reducing downtime significantly. These innovations are reshaping industries— but what happens when they hit a snag?

The choice you make today could define the trajectory of your business tomorrow. What happens next shocked even the experts...

When investing in a packaging machine, the upfront cost is just the tip of the iceberg. Maintenance, repairs, and updates can quickly add up, turning a seemingly cost-effective decision into a financial burden. Unforeseen expenses are often hidden in service contracts that can blindside even the most astute business owners.

Moreover, energy consumption is a significant factor often overlooked. Machines may claim energy efficiency, but real-world usage can tell a different story. It's crucial to calculate the operational costs over time, which can dwarf the initial investment. But there’s one more twist…

Not every machine suits every product type. A one-size-fits-all approach could lead to operational inefficiencies and product waste, costing dearly in both money and resources. Choice specificity can mean the difference between profitability and loss!

But what you read next might change how you see this forever. Choosing carefully isn’t enough if you overlook critical features that ensure long-term success—features many industries are still discovering every day.

Imagine investing in a state-of-the-art machine only to discover it can’t handle your specific product dimensions or weight. This mismatch can lead to inefficiencies, delayed production times, and unnecessary complications. Being vigilant about machine specifications saves not only time but also a lot of money.

Different products have different needs: liquids require special sealing solutions; fragile items need gentler handling. A misalignment in machine-product compatibility could lead to damaged goods, customer dissatisfaction, and even reputational harm. And there's more to consider…

Real-time customization is transforming the game. Machines that adapt on-the-fly to product variances not only save costs but also improve product consistency and customer satisfaction. This level of flexibility was once a dream for many industries but is now becoming a standard expectation.

The importance of future-proofing your investment cannot be overstated. As product lines evolve, so too should your packaging capabilities. Failure to anticipate these changes could leave you scrambling to upgrade prematurely—taking a severe hit on your budget.

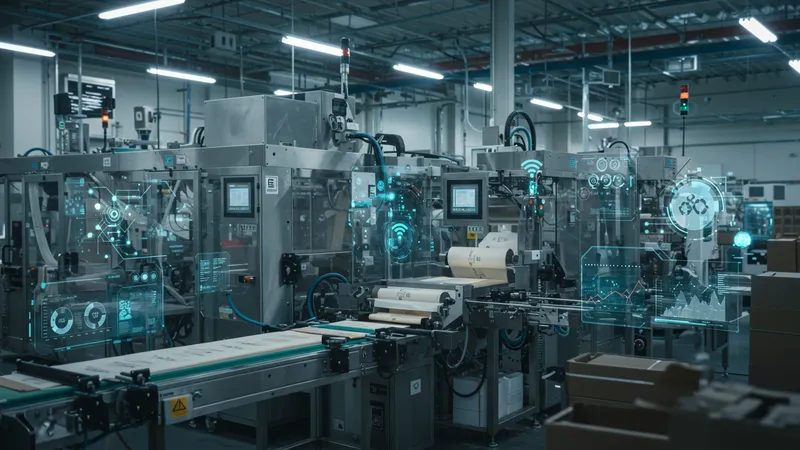

The Internet of Things (IoT) is radically transforming packaging lines, offering insights that were previously out of reach. Machines equipped with IoT capabilities provide real-time analytics that streamline processes and predict potential faults before they become costly problems.

The data these smart machines generate can track performance, highlight inefficiencies, and enhance productivity. Insights gained from IoT data not only optimize production but also guide strategic decision-making, keeping businesses ahead of the competition.

But IoT goes beyond just efficiency enhancements—these systems enhance safety by monitoring operating conditions and identifying potential hazards. This proactive approach prevents accidents and ensures compliance with stringent industry standards, safeguarding both employees and investments.

This IoT-driven revolution is not without its challenges, however. Ensuring data privacy and system security is paramount. As more machines become interconnected, the threat of cyber-attacks rises. Businesses embracing IoT must prioritize robust cybersecurity measures to protect their valuable data.

Artificial Intelligence (AI) is redefining packaging by delivering precision and personalization at scale. AI systems can adjust machine settings in real-time, based on data inputs, optimizing performance without human intervention. This level of ingenuity was once science fiction, yet today it's a practical reality.

These intelligent systems learn from patterns, continuously improving their efficiency and effectiveness. For instance, AI can predict maintenance requirements, thus preventing unexpected downtimes and extending the lifespan of machinery. A game-changer for maintaining productivity!

Moreover, AI-driven machines offer unparalleled precision—reducing waste, improving accuracy, and ensuring consistency across large volumes. Consistency is key in maintaining brand trust, and AI machines are fast becoming the gold standard in the industry.

Yet, with this power come ethical considerations, like the reduction of human oversight in critical areas. The balance between embracing AI innovations and ensuring human jobs isn't lost forever is the new frontier companies must navigate wisely.

Sustainability is more critical than ever, and packaging technology is at the forefront of this movement. Innovations have made it possible to prioritize eco-friendly practices without sacrificing quality or efficiency. More businesses are now adopting biodegradable materials and energy-efficient machines.

Choosing sustainable machines isn't just an ethical consideration; it's also a strategic decision. Consumers increasingly demand environmentally-conscious choices, and brands that meet these expectations enhance their market appeal and trust. The stakes are high!

Aside from boosting brand loyalty, sustainable packaging solutions often lead to cost savings. Energy-efficient machines reduce power consumption significantly, while waste reduction technologies minimize raw material use, thus cutting expenses.

But the journey doesn't end there. As regulations around packaging waste continue to tighten, companies must remain vigilant, ensuring they're compliant and competitive within the evolving landscape of sustainability.

Packaging is more than just a means to an end; it's a powerful communication tool. The right packaging machine influences how consumers perceive your brand, offering a consistent, high-quality experience that reinforces brand identity with every interaction.

Packaging that enhances product protection and appearance contributes to customer satisfaction. Well-designed packages are more likely to capture attention on crowded shelves, fostering a positive first impression and increasing the likelihood of purchase.

But packaging also tells your brand story. From the choice of materials to the packaging style, every detail communicates core values to your target audience. Whether opting for sleek, modern designs or rustic, sustainable materials, the right choice can elevate your brand image significantly.

The impact of strategic packaging choices cannot be underestimated. In today's competitive market, standing out requires aligning every packaging decision with your brand ethos. Are you ready to take that leap and transform your brand perception for the better?

Integrating new packaging machines into existing supply chains often presents unforeseen challenges. Compatibility issues with current systems can cause significant disruptions, potentially hindering production and impacting overall efficiency.

Efficient supply chain integration requires thorough planning and collaboration across departments to ensure smooth implementation. This is where expert insights can prove invaluable, saving time, reducing costs, and avoiding common pitfalls.

There's also the consideration of downtime during the transition period. Coordinating schedules to minimize production stops is crucial. A well-executed integration plan not only mitigates these risks but also enhances operational success and productivity.

What you read next might reveal surprising insights into overcoming these challenges using cutting-edge technologies and innovative strategies that are transforming supply chain management worldwide.

Businesses that delay investing in new packaging machines often incur hidden costs that surpass the initial outlay of an upgrade. Continuing with outdated technology leads to inefficiencies that compromise speed, reliability, and product quality.

Older machines can’t offer the modern features that consumers and industry standards increasingly demand, such as enhanced personalization or sustainable practices. This lag can erode competitive advantage, leaving businesses playing catch up.

Furthermore, increased maintenance costs associated with aging equipment can become burdensome. Frequent repairs lead to prolonged downtimes and lost productivity, impacting the bottom line significantly.

But there's a silver lining—progressive investments in new technology not only streamline production but also prepare companies for future market trends, ensuring sustainability and long-term success.

Investing in state-of-the-art machinery is pointless if your workforce isn’t trained to utilize it effectively. Changes in technology can be daunting, leaving employees feeling overwhelmed and resistant to new processes.

A comprehensive training program equips your team with the skills needed to manage new machines confidently. Well-trained staff are more efficient, effective, and motivated, significantly boosting production and morale.

Moreover, continuous professional development keeps teams abreast of industry-standard practices, which in turn enhances competitiveness. Employees who feel valued and empowered are more likely to commit long-term, reducing turnover rates.

As automation grows, the role of the human element becomes even more crucial. Successful integration of technology and human expertise is the key to thriving in an ever-evolving landscape. But wait—there's one more angle to consider...

The packaging industry stands on the cusp of a technological revolution, heralding advancements that were once mere concepts in science fiction. From smart packaging that monitors freshness to robots that adapt to variable production environments, the future is here.

Augmented Reality (AR) in packaging promises to enhance consumer interaction, offering immersive experiences that transform mundane tasks into engaging activities. Picture scanning a product package with your smartphone and instantly accessing personalized content.

Additionally, innovations like biodegradable electronics integrated into packaging could drastically change our approach to waste management. This intersection of tech and sustainability opens exciting new possibilities for environmental impact reduction and efficiency gains.

The challenge lies not only in adopting these innovations but also in integrating them seamlessly with existing systems. Being part of this evolution requires forward-thinking strategies and open-mindedness towards experimentation. But the payoff could redefine success as we know it.

Choosing the right packaging machine boils down to understanding your specific production needs. There’s no one-size-fits-all solution, so assessing your product line, volume, and growth plans is essential to making an informed decision.

Researching reputable suppliers is the first step. A trusted partner will help navigate the complexities of machinery choices, offering tailored solutions that align with your business aims and budget constraints.

A critical factor is the machine’s scalability. As your business grows, your machine should be able to adapt to increased demands without compromising on performance or quality. Future-proofing your investment is key to sustaining growth.

Finally, consider after-sales support and warranty offerings. Peace of mind comes from knowing expert assistance is available when needed. With these considerations, the perfect packaging solution is within reach—preparing your business to soar to new heights.

The saga of choosing the right packaging machine culminates not in uncertainty, but empowerment. You now hold the knowledge and insights needed to conquer the challenges and seize the opportunities of modern packaging solutions. Your next step is crucial—take action, share your newfound wisdom, and watch your business thrive as you embrace innovative packaging technologies!