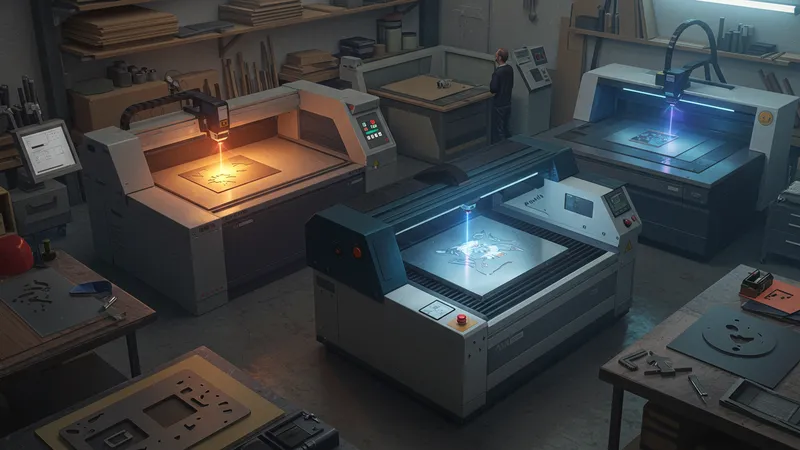

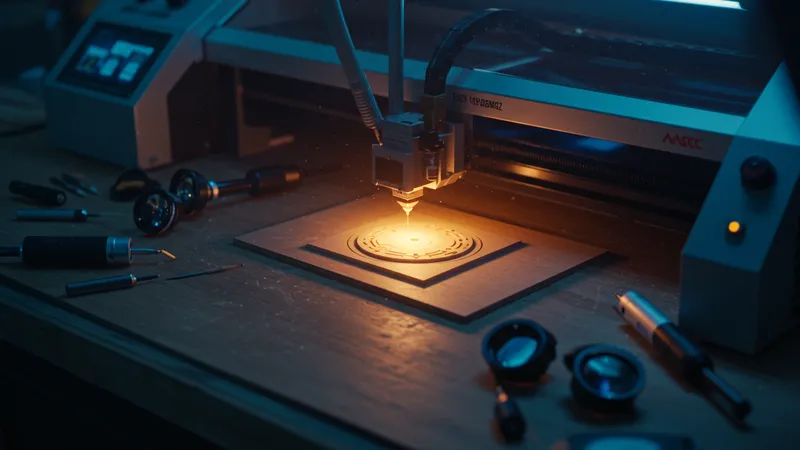

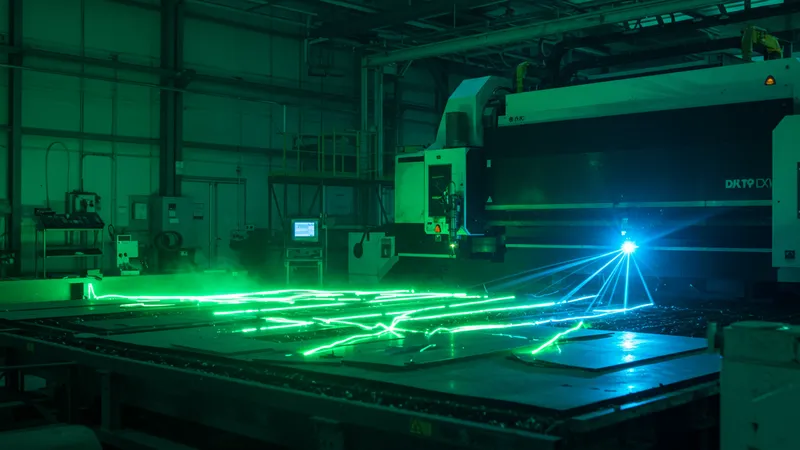

Did you know that a laser cutter can slice through metal like butter with pinpoint accuracy and even engrave incredibly intricate designs? It’s a game-changer for artists, hobbyists, and industrial professionals alike.

In today's digital era, the demand for personalized, precise creations has skyrocketed, making laser cutters indispensable. But navigating the myriad of options can be overwhelming. Here's why more people are investing in this technology today.

Surprising though it may seem, laser cutters are not just industrial giants. They are becoming fixtures in home workshops across the globe, enabling unprecedented creativity. You might associate this tech with hefty prices and expertise, but consumer models are breaking down these barriers. But that’s not even the wildest part…

No longer restricted to metals, modern laser cutters can process a dizzying array of materials: wood, acrylic, leather, and even glass. Customization has never been this accessible, and each cut tells a story of innovation. But here’s a twist: some machines even feature AI-driven functionalities that optimize efficiency in ways you won’t believe. But that’s not even the wildest part…

So, what should you consider when buying a laser cutter? Understanding variations in laser types, power, and capabilities can make or break your purchase decision. But it's the unexpected trend that's turning heads in the industry. What happens next shocked even the experts…

Most buyers anticipate the initial expense of a laser cutter, but the unforeseen costs are where surprises lurk. Maintenance, software upgrades, and energy consumption can quickly chip away at your budget. Many find these surprises only after their first big project, often with price tags adding up to hundreds or even thousands per year. But there’s one more twist…

While pricier models boast enhancements and longevity, sometimes basic models outperform their costlier siblings in specific tasks. An insider tip: prioritize based on your immediate needs rather than future aspirations. Quality over quantity takes on new meaning when you consider the frequency of use versus potential idle time. It’s a complex balancing act that many newcomers don’t initially grasp. What you read next might change how you see this forever.

Another intriguing aspect often disregarded is the resale value of laser cutters. Unlike most electronics, these machines can maintain high resale values if properly maintained. It's a rare trait indeed, offering a safety net for those worried about their initial investment. That said, not all models hold their worth equally; thorough research becomes essential to optimize your investment.

You may not believe it, but leasing becomes an enticing option for those hesitant to commit. Rather than an all-in purchase, leasing can provide access to high-end features without the hefty initial cost. Industry veterans have been leveraging this strategy to test varying capabilities before making a permanent decision. Now that exclusive leasing options are trickling down to smaller business owners and hobbyists, it's a trend worth exploring.

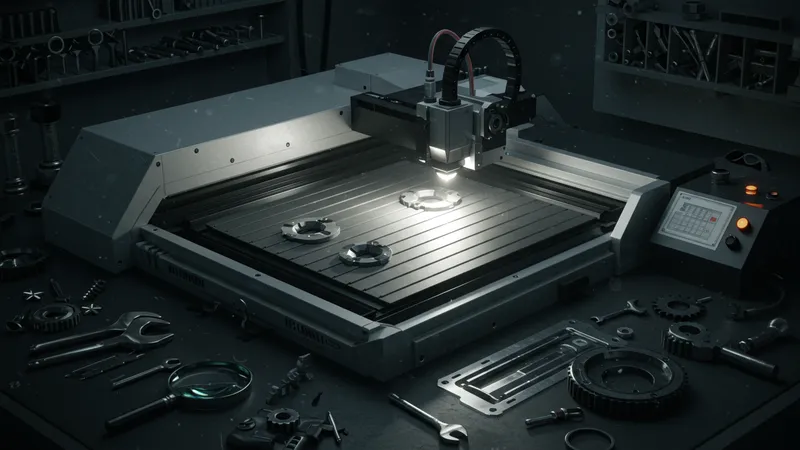

Beyond the basics, laser cutters are evolving with automated features that make life considerably easier for operators. Picture this: software that computes the most efficient paths in real-time, minimizing material waste and maximizing output. Innovators have refined these capabilities, bringing industrial-level efficiency to small studios. But there's a quirk you wouldn't expect…

Here’s a curious nugget: some models now include “smart” air filtration systems that adjust clouding depending on the material and its density, safeguarding both your health and your surroundings. It’s these hidden gems that elevate your crafting game from basic to pro. Such innovations often become the much-needed tiebreaker when deciding between two competitive products.

In terms of adaptability, modular designs are now available, allowing users to add or swap components per evolving needs. This modular leap grants scalability previously reserved for significantly larger setups. Imagine upgrading your machine functionality as effortlessly as updating software. It's a game-changing flexibility that minimizes financial pressure over time.

Yet, all these tantalizing features pose a pressing inquiry: how do these enhancements measure up in real-world scenarios? Often, it’s the subtle upgrades that make significant differences, streamlining complex processes that once required multiple machines and extensive manpower. But here’s the kicker—it might make your future projects simpler than envisaged.

Choosing between models often involves an often-overlooked factor: availability. Due to high demand, many top-notch laser cutters experience long delays for restocking. It's not uncommon for waiting periods to stretch over several months. Some enthusiasts have cleverly sidestepped this issue by monitoring industry forums for early insider tips. But there’s an unexpected angle…

Interestingly, warranties on laser cutters vary widely in coverage. Whereas some offer comprehensive plans that cover almost every part for multiple years, others might limit coverage to only specific components. Paying attention to warranty details could save significant expenses down the line. It’s your early-warning system against surprise breakdowns.

Loyalty programs starting to surface among manufacturers are another unexpected trend. These plans reward repeat customers with exclusive discounts and early access to new models. Such initiatives can make a substantial difference for those regularly upgrading or expanding their workshop capabilities.

However, the most impactful revelation might be the emerging practice of community-driven warranties, where users band together to share parts and assistance. It’s a grassroots innovation fostering a tight-knit community and mutual support. Communities are transforming the landscape, turning individual challenges into collective solutions. Meanwhile, as you delve further, there's yet more to uncover.

While working with laser cutters, users are frequently taken aback by material limitations that are not immediately apparent. Different lasers interact with materials uniquely, affecting precision and quality. Understanding these intricacies can be the decisive factor between triumphant success and dismal failure. But here’s an intriguing twist…

Recent advancements have introduced adaptable lasers capable of accommodating varied materials more efficiently. These developments translate into immensely broadened creative possibilities, fueling ambitious projects that were once only dreams. For existing owners, upgrades present a relative advantage, as those reluctant to switch models find themselves clinging to dwindling capabilities, subtly constraining their creative scope.

What is often left unspoken is the effect of humidity and temperature on material handling. Operations in uncontrolled environments can render unnecessarily coarse or irregular results. By investing in climate control, many achieve consistently superior outputs. These nuanced tactical shifts reflect profoundly in the end products’ aesthetics and durability.

Many seasoned craftsmen experiment with unconventional materials, pushing boundaries into uncharted territories. These gutsy adventures lead to remarkable discoveries that regular users rarely explore. Who would have expected textile laser printing to gain traction as a custom solution in the fashion industry? The tides of possibility seem ever-shifting in this vibrant domain.

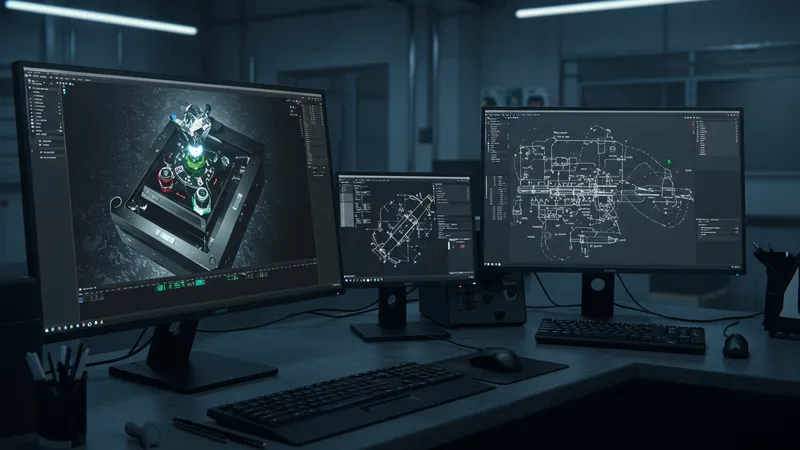

Crafting with precision is as much about software as it is about the hardware. Yet, the software often fades into the background of consideration, despite its hefty influence on operational efficiency. User-friendly interfaces vastly enhance workflow, translating complex tasks into achievable feats. But that’s not the entire story…

Notably, certain software suites cater specifically to industries, from jewelry to aerospace, with dedicated modules amplifying accuracy and artistry in sector tasks. Gems like these often fly beneath the radar but attract those in the know. This sector-specific software can become indispensable once integrated, unlocking techniques few contemporaries can rival.

Cloud integration now allows projects to be stored, shared, and modified across company networks seamlessly. This innovation grants collaborative power like never before, lowering the barriers hindering team cohesion. It’s this bridge that propels smaller yet nascent teams into operating with larger firms' efficiency. Ever wondered how this trend reshapes traditional crafting boundaries?

These software enhancements come with risks, though: regular updates demand vigilance to protect from bugs or oversights. Frustrations multiply when workload is paused, awaiting patches or robust solutions. It’s a technological dance, where staying updated equates to embracing cutting edges, while stagnation can lead to backslides. Such a dynamic arena commands commitment from its operators.

The ecological impact of laser cutters seldom enters mainstream conversations, yet it's rapidly emerging as a critical discussion point. The cost of consumables, emissions, and energy is heavily scrutinized, leading to a reevaluation of practices among eco-conscious entities. This awakening isn’t without surprising insights…

Cleaner, greener technologies are being developed that use less power while optimizing effectiveness. Some new models integrate solar-powered options, significantly reducing carbon footprints. Adoption of such innovations isn’t widespread yet, but it's gradually gaining traction as consumer awareness and demand increase. It’s an evolution towards sustainable creativity driven by consumer choice.

Online forums thrive with discussions on recycling leftover material. Many enthusiasts share innovative strategies for repurposing scrap, a field ripe with potential for environmentally mindful makers. Collaborative recycling initiatives proliferate, uniting creatives towards common goals. Could this pave a sustainable path forward for mass production?

Despite rising environmental concerns, implementing green technologies requires confronting budgeting challenges. Initial costs can be a deterrent, but informed choices today may dispel cost considerations tomorrow. Progress in this area carries a ripple effect across industries, illuminating pathways through responsibility-laden landscapes, steering ingenuity towards collective responsibility. Yet, as these evolving dialogues continue, what’s next on the horizon?

Accessories for laser cutters are more than mere add-ons; they’re transformative amplifiers of primary functionalities. Whether enhancing accuracy, extending durability, or improving ease-of-use, these additions can redefine your crafting possibilities. The array of choices is staggering yet understated. Delve deeper, and here’s a surprising realization…

From rotary devices expanding cylindrical capabilities to specialized lenses that fine-tune focus, accessories can refashion what seemed static into dynamic ventures. A pulse of innovation beats steadily in accessories that provide newfound versatility. As suppliers grow, the marketplace swells with innovative potential, surprising even veterans.

Some lesser-known attachments, like enhanced exhaust systems, significantly impact lifespan and functionality. These systems advocate for cleaner outcomes and healthier work environments, often overlooked advantages in high-octane production settings. Notably, some countries have started integrating accessory standards, harmonizing domestic markets with international expectations.

Not all innovations catch mainstream attention initially, leading to missed opportunities. Therefore, collaborations between accessory and main unit manufacturers are becoming increasingly vital in advancing technology congruently. A thriving exchange between these sectors can unlock staggering breakthroughs. Is the accessory revolution silently reshaping the industry grounds right under our feet?

The uncelebrated truth about laser cutters is that maintenance is the quiet guardian of efficiency and longevity. Consistent checks and care can double machine life and performance, yet neglect casts a long shadow over potential. Maintenance unexpectedly proves itself a potent companion…

Neglected optics and unattended components result in degraded precision and marred results. Vigilance is key, revealing its rewards over time. Establishing a regular maintenance schedule aids in achieving peak performance and confidence in output quality. Overlook this at your peril, for even the best equipment falls to neglect.

Manufacturers are increasingly providing maintenance kits targeting self-reliant users, subtly shifting paradigms from external dependents to empowered consumers. Detailed instructions accompanying these kits demystify upkeep processes, instilling operational competence and self-assurance.

Moreover, the evolving ecosystem of service providers that offer on-demand tune-ups reflects an industry catering to schedules rather than clients adjusting to fixed cycles. Convenience fosters adaptation, crucial in sustaining equipment longevity. This is why evolving maintenance protocols potentially hold the key to revolutionizing user relationships with their tools.

While lasers slice metals and woods with ease, their reach extends into the social fabric, transforming the very essence of creativity and entrepreneurship worldwide. Enabling personalized craftsmanship, these machines fuel dreams and spawn business ventures once deemed improbable. But there’s more underpinning this shift…

The cultural adoption of laser technology catalyzed local artist empowerment, particularly in regions formerly bereft of high-tech accessibility. Empowered individuals advocate for personal expression through newfound mediums, weaving unique narratives into collective history. The rise in custom gifts and bespoke artistry illustrates these evolving cultural narratives enthusiastically embraced by communities.

Laser cutters also contribute to educational growth. Schools incorporate design and engineering programs in curriculum via practical examples. By cultivating technical acumen alongside creativity, future generations are poised to lead business innovations confidently, shaped by hands-on experiences at the intersection of art and technology.

While opportunities abound, accessibility remains disparate. Addressing inequality, focused initiatives strive towards broader introductory programs and skills workshops, seizing upon the inquisitive spirit driving technological adoption. Facilitated access ensures more equitable distribution of technological empowerment. Yet, how might continued efforts in spreading laser cutter utilization shape our futures?

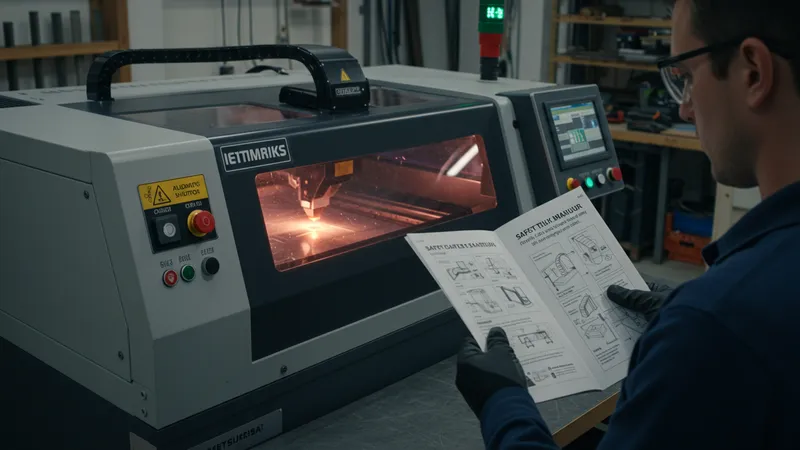

The silent potency of lasers demands acute attentiveness to safety, guarding against dangers an untrained eye might miss. User safety fundamentally rests on integrating vigilant practices alongside everyday operations. But by what routes is safety integrated seamlessly into workflows?

Vigilance is pivotal, reflected in safety mechanisms embedded within latest models such as automatic shutoffs during misalignment or blockage. User manuals rich with comprehensive guidelines offer vital knowledge, though often under-emphasized amidst initial excitement. Preparation constructs an invisible shield protecting users against unexpected pitfalls.

Work environment plays a crucial role in maintaining safety. Adequate ventilation systems counteract hazardous fumes, converting toxic exposures into safe breathable environments. Proactive implementations ensure incorporation into design phases, championing health and safety consistently.

Yet, barriers persist. Unqualified shortcuts can compromise safety, necessitating collective reminders that cutting corners holds irreversible consequences. Elevating safety goes hand in hand with evolving awareness campaigns, leveraging communities to mutually safeguard participant well-being. In these shared spaces, safety education evolves alongside technical marvels.

The evolution of laser cutting is compelling, its trajectory guided by continuous innovation. From present to future, transformative potential persists in endless iterations awaiting discovery—reflections of visionary dreams. Yet, the undercurrents guiding this inexorable advancement merit exploration…

Towards achieving sustainable methods, fusion technologies currently in development promise integral power efficiency at unprecedented scales. Such transformations within industrial paradigms nod towards eventual discovery of harmony between productivity and preservation. These sustainable drives serve aspirations for technology aligned with environmental consciousness.

Virtual reality integrations reveal possibilities unfathomed until recently, blurring demarcations defining imagination and reality. Envision sculpting designs within immersive virtual playgrounds before materializing perfection. Industry insiders herald these augmented realities as creative toolsets reshaping traditional lofts.

Society progresses through communities embracing shifts, leveraging collective capabilities toward shared goals. More profound than technological marvels, such acceptance weaves inclusivity and democratization into the fabric of evolving legacies. As laser technology maps unknown landscapes, one persistent refrain echoes: how might collective harnessing of shared destinies coalesce into potent reality?

As you’ve traversed this multifaceted journey into the realm of laser cutters, the revelation lies not merely in the intricate details but the realization that this revolutionary tool is as much a catalyst for change as it is a cultivator of creativity. The possibilities they present are bound only by the limits of imagination and access.

Your next steps matter. Delve deeper, consider how laser technology could be your creative or business ally, and share these insights. Spread the inspiration, bookmark this guide, and join the conversation that continues shaping the future of innovation. Imagine, create, and let others in on the newfound wisdom of laser cutting.