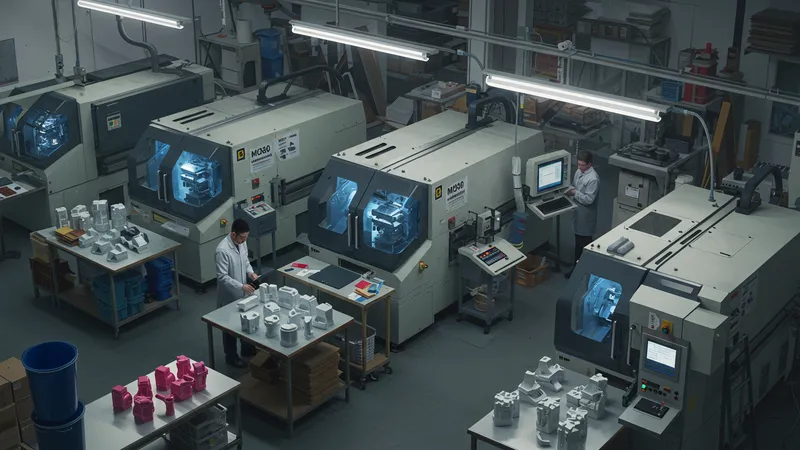

Imagine a world where manufacturing is transformed overnight, thanks to the unexpected rise of advanced molding machines in 2025. Yes, these game-changers are not just revolutionizing industries—they are redefining them. But is it all as smooth as it seems?

With the ever-evolving demands of modern manufacturing, understanding these pivotal tools is crucial. As technology races forward, so must our knowledge. Dive with us into the shocking world of molding machines that are reshaping the industry more than ever before.

One astonishing development is the dramatic drop in production time that these machines offer. Previously, creating complex components took days, but now it only takes hours. This efficiency surge didn't just make headlines; it caught the attention of industries everywhere. Yet, the real surprise lies ahead…

Contrary to popular belief, not all molding machines are created equal. While some promise speed, they may compromise quality—a trade-off many companies cannot afford. But what if there was a way to avoid this dilemma entirely? Keep reading because the most unexpected part is yet to unfold…

This year alone, technological advances in these machines have blindsided even seasoned experts. New features and integrations are launching faster than companies can keep up with. What happens next shocked even the experts, and you won't believe who stands to benefit the most…

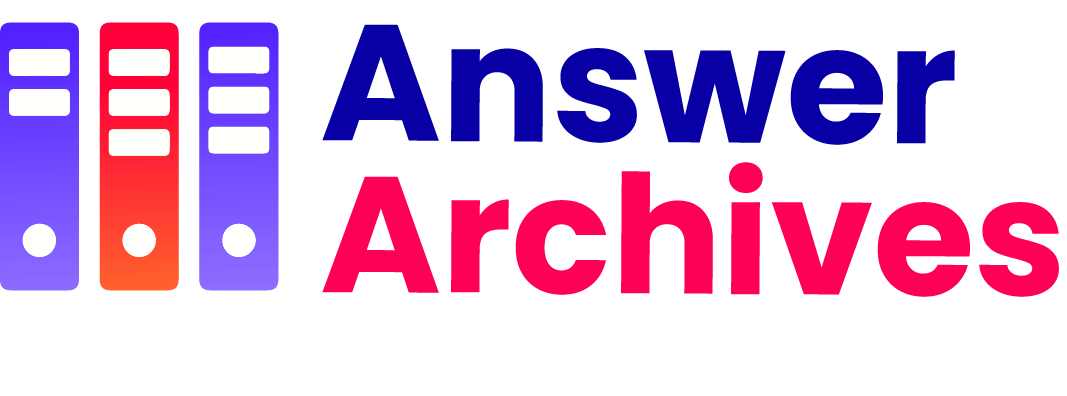

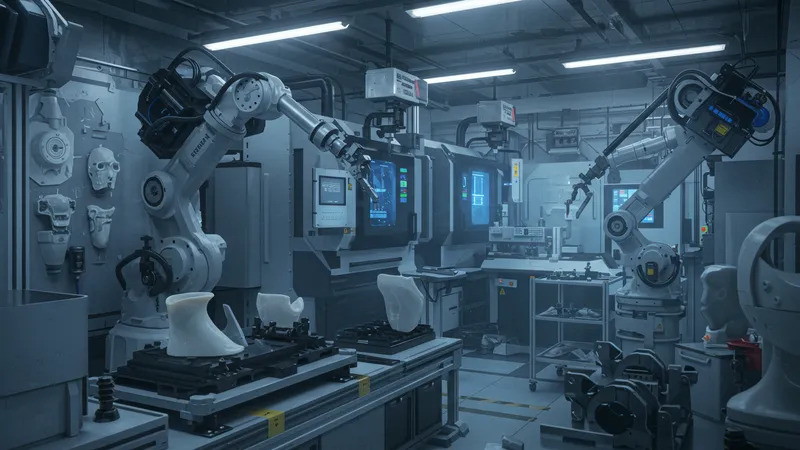

Smart technologies are weaving their way into every aspect of our lives, and the world of molding machines is no exception. The ability to program a machine that learns and adapts sounds like science fiction, but in 2025, it's a reality for many manufacturers. Productivity has soared, but there’s one more twist...

These next-gen machines are equipped with sensors that predict maintenance needs before any breakdowns occur, drastically reducing downtime. Before, unexpected halts could cost companies millions. Now, such interruptions might be a thing of the past. But what you read next might change how you see this forever.

Imagine a future where a machine not only produces items faster but does so with precision down to a micron. With such technology, the scope for error is minimal, saving resources and boosting efficiency exponentially. But could there be hidden trade-offs?

Certain challenges still linger, such as software integration issues where older systems can't communicate with cutting-edge technology. This can lead to unexpected costs and delays. The next topic reveals the repercussions of these challenges...

The environmental toll of manufacturing has been under scrutiny for decades, but recent advances in molding technology offer hope. Machines now incorporate energy-efficient designs that significantly cut energy consumption—an evolution that could reduce industrial carbon footprints dramatically.

The use of biodegradable materials in the molding process is also on the rise, combining sustainability with innovation. These eco-friendly options have stirred excitement but also raised questions about their long-term effectiveness and cost implications.

Despite their promise, the transition to green technologies isn't always seamless. The initial investment can be daunting, and for some players, the savings might not justify the costs. But, there’s an unexpected curveball to this narrative...

As with any burgeoning technology, the absence of extensive data on long-term consequences poses a risk. While initial results are promising, the full impact of these green technologies is yet to be seen. What's unveiled next might just change everything...

At first glance, the price tags on advanced molding machines might seem prohibitive. However, when seen through the lens of long-term savings, they tell a different story. Many companies report recouping their investments within less than five years due to increased output and reduced waste.

Investing in these machines could broaden profit margins, but there's a catch. Not every business is positioned to take on these upfront costs, which could create a divide between industry giants and smaller operations.

Despite the economic advantages, the transition isn't without its challenges. Fluctuating market conditions and material costs continue to pressure companies to rethink their strategies. But there’s a potentially game-changing aspect worth considering...

With emerging financing options designed specifically for this industry, even small-to-medium enterprises can get a piece of the pie. What you learn next might completely redefine business strategies and investments in the sector...

The capabilities of molding machines in 2025 extend far beyond conventional roles, creating endless possibilities across industries. From bespoke medical devices to aerospace components, their precision and efficiency are opening new frontiers. Who could have imagined such diversification a decade ago?

In the medical field, personalized implants and prosthetics are now feasible on a mass scale. This isn’t just transforming patient care but also setting new industry standards. But there’s an even bigger story to this transformation...

Meanwhile, in the automotive industry, lighter, more fuel-efficient parts reduce emissions, aligning with global initiatives for greener transportation. However, these benefits come with their own set of challenges...

As sectors continue to push boundaries, the competition to innovate becomes fierce. The winner isn’t necessarily the fastest or the cheapest but the one that adapts best. What you discover next might reveal a competitive edge you didn’t know existed...

Gone are the days of one-size-fits-all solutions. Today's consumers demand highly customizable products, and molding machines are answering the call. By accommodating intricate designs and varied materials, manufacturers are meeting demands like never before.

This drive for customization is creating a ripple effect. Businesses are experiencing a surge in demand for bespoke products, propelling them into new markets. But there’s a hidden factor that could amplify these opportunities...

With advanced software driving customizations, the barrier to unique designs is becoming almost negligible. The possibilities seem endless, yet there’s a twist to this tale that companies must navigate carefully...

As more companies adopt customization, the pressure to maintain speed and quality mounts. Innovations that streamline this process without sacrificing standards will determine the next market leaders. What follows could redefine the ground rules completely...

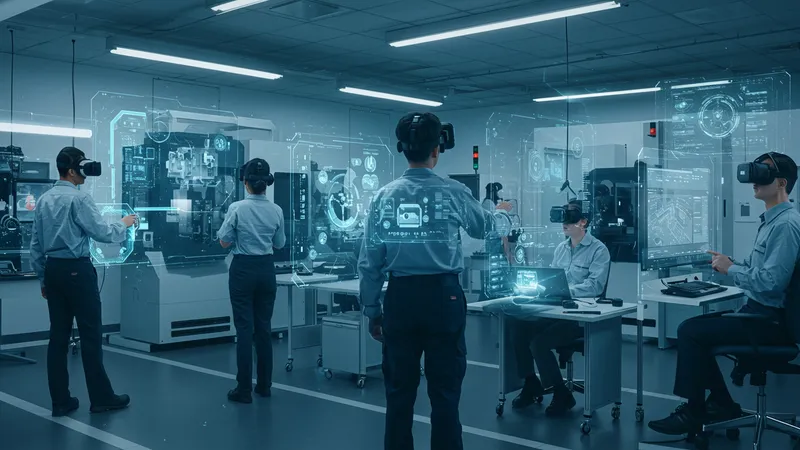

As technology progresses, so do the skill sets required to operate it. Training programs for advanced molding machine operators are digitalizing, offering virtual experiences that enhance learning and retention.

These programs are not just streamlined for efficiency but also making room for diverse education backgrounds to enter the field. This democratization of skills is setting new precedents, but what about its limitations?

Despite the robust curriculum, real-world practice remains irreplaceable. While virtual models present information, the unpredictability of hands-on experience is invaluable. Yet, education is evolving in unexpected ways to bridge this gap...

Micro-credentialing and continuous professional development ensure that workers remain at the cutting edge. This evolution in skill acquisition might change the workforce dynamics of tomorrow entirely...

Success in implementing 2025 molding technologies ranges widely, and several companies have emerged as poster children for these advancements. Their journeys illuminate both the promises and perils of this new era.

Some have seen exponential growth and heightened market share by effectively leveraging new capabilities. But not all stories are triumphs—failure to adapt quickly has left others by the wayside...

Lessons from these case studies offer crucial insights into strategic decision-making and stress the importance of agility. While some companies wear adaptation as a badge of honor, others falter, revealing deeper systemic issues...

Analysis indicates that those who thrive embrace both technology and innovative culture. What you learn next from these stories can be a blueprint for industry practices moving forward...

The trajectory for molding machines in 2025 indicates continuous advancement and integration across more sectors. As capabilities expand, so do the possibilities for new applications and innovations.

Emerging trends point toward even more sophisticated AI enhancements and improved ecological footprints, positioning these machines as keystones in building future industries. But this future comes with its own set of uncertainties...

With fast-paced technological change, the need for flexible strategies grows. Businesses must be stalwart, ready to pivot as new challenges and tech emerge, constantly evaluating cost-benefit landscapes...

A bold prediction or two might just see not only what is feasible today but also into revolutionary horizons. Understanding where this path might lead will be pivotal for tomorrow’s leaders. This journey is only beginning...

The landscape of molding machines in 2025 is a testament to technological prowess and industrial foresight. With each innovation, the line between what's possible and what's practical continues to blur.

As these machines redefine industries, staying informed and adaptable will be crucial. Share these insights, bookmark them, and remain engaged with the continual evolution of molding machines—it's a story that’s far from over.