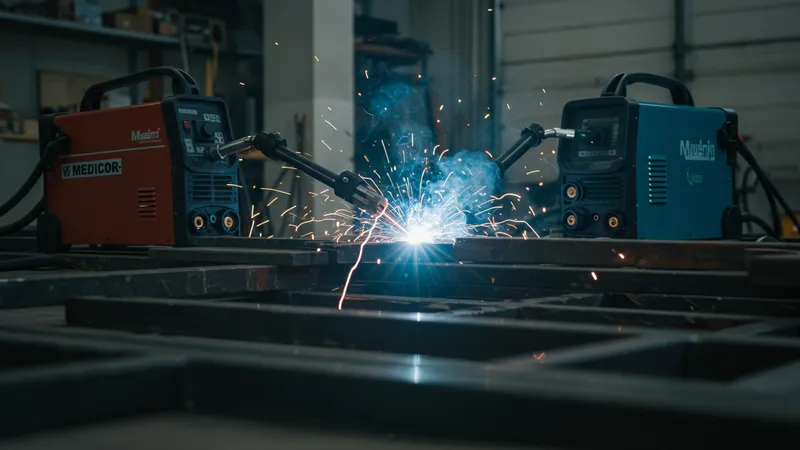

Did you know that a device used in producing skyscrapers might be more accessible and versatile than you ever imagined? Welding machines are revolutionizing more than just construction.

As industries pivot and adapt faster than ever, understanding welding machines is crucial for professionals and DIY enthusiasts alike. Their multifaceted applications could surprise you!

Welding machines aren't just for massive construction projects. Home workshops and artists are sparking creativity using these power tools. From crafting metallic art to repairing crucial farm equipment, welding machines have found a home in every corner of the creative and industrial world. But that’s not even the wildest part…

Did you know there are more than five types of welding machines, each with a distinct edge? Machines designed for a specific type of welding process unlock different potentials — from creating art to reconstructing urban infrastructure. What happens next shocked even the experts...

Mig welding, or Metal Inert Gas welding, is arguably one of the simplest techniques to master, yet it’s involved in the creation of massive steel structures. It uses a continuous feed wire and has a protective gas flow. Its ease of use makes it popular for beginners, yet versatile enough for pros. But there’s one more twist…

The true beauty of Mig welding lies in its adaptability across different materials, including stainless steel and aluminum. This flexibility has empowered DIYers and industrial manufacturers alike. What you read next might change how you see welding forever.

Many do not realize that Mig welding is not just limited to clean environments. Specialized setups allow for crucial fixes on-site in outdoor conditions. This adaptability makes it indispensable and contributes to its growing demand across various sectors. But wait until you hear about the secret behind its efficiency…

The coatings used in conjunction with Mig welders can significantly affect the quality of the weld, enhancing aesthetic appeal and durability. Next time you admire a gleaming metal fixture, remember that it likely owes its sheen to meticulous Mig welding. But that’s not even Mig welding's standout feature...

Tig, or Tungsten Inert Gas welding, is revered for its precision and control, allowing welders to create stunning detailed work. Often seen in art and high-end applications like aircraft, it requires dexterity and skill. But Tig welding’s influence stretches beyond art...

The process might be slower, but this is paradoxically one of its strengths, enabling intricate designs and stronger welds. Its capability to weld non-ferrous metals like magnesia and aluminum sets it apart. But the real revelation is still to come.

Many artisans who swear by Tig appreciate its cleaner finish, courtesy of the non-consumable tungsten electrode which ensures minimal contamination in the weld. Want precision welding? Tig is your answer. And here’s the kicker—you can even tackle underwater projects with specialized equipment.

While Tig’s demand for skill might be daunting, it spurs innovation among professional welders dedicated to mastering its elegant applications. And that's just scratching the surface. What you don’t know about Tig welding’s role in the medical field might surprise you...

Often overshadowed by Mig and Tig, Plasma welding is a hidden gem of the industry. Similar to Tig, it relies on a tungsten electrode and produces a more focused jet of plasma for high precision. But these aren’t its only shocking qualities...

This method is praised for cutting intricate patterns in metals quickly, which is critical in high-volume production scenarios like automotive manufacturing. Its precision isn't just impactful; it might just redefine how industries approach mass customization. But that’s not the end of plasma’s story...

It's not widely known, but Plasma welding boasts capabilities comparable to laser cutting, often at a fraction of the cost. This affordability while retaining precision makes it a game-changer for emerging markets and startups. But here's the unexpected truth—its successful integration in delicate operations like electronics is a marvel.

The plasma realm isn’t restricted to welding alone; its technology is being adapted to other applications, breaking new ground in areas you wouldn’t expect. The next evolution of welding and beyond is in motion. Ready to explore the role of robotics in welding?

Enter the future—robotics are now an integral force multiplier in welding, promising increased efficiency and consistency. Automated welding systems are now necessities rather than luxuries in large-scale manufacturing. The results are extraordinary...

Robotics enhance precision and safety, handling hazardous environments that might pose risks to human workers. Industries leveraging automated welding machines report skyrocketing productivity. Yet the robotics story is far from over...

The real breakthrough lies in their learning capability. Advanced systems now employ AI to adapt to new materials and complex geometries without human intervention. This self-improvement already has industries rethinking process designs. But there's more insight to come...

Are welders becoming obsolete? Not quite! Humans are still crucial for oversight, repair, and strategic manual interventions. With such symbiosis between man and machine, the welding profession is evolving dramatically. Next, let’s explore the sustainability angle of welding technologies...

As the world leans towards sustainability, welding technologies are adapting to reduce environmental impact. Eco-friendly welding is not just a buzzword; it’s becoming established practice with real results. Here's where it gets fascinating...

Processes are being fine-tuned to reduce waste and improve longevity of materials, reducing the need for additional resources. Innovations like cold welding, requiring no heat, are emerging champions of green technology. But this isn’t quite everything...

Welding's contribution to renewable energy sectors, such as in the assembly of wind turbines, is crucial for green progress. Enhancing weld efficiency is directly translating into lower carbon footprints and heightened ecological responsibility. Yet there’s another side to this narrative...

Manufacturers now prioritize energy-efficient welding machines, greatly conserving electricity in industrial settings. This shift doesn't just benefit the planet; financially, it represents a significant advantage. But where does this transformation journey lead next in our welding exploration?

Understanding materials is key to perfecting the weld. The shift from traditional steel to advanced alloys and composites is redefining industry expectations. This isn’t just about strength; it truly is an alchemical transformation...

These new-age materials require innovative welding techniques due to their unique properties. Successfully welding titanium, for example, demands immaculate attention to environmental conditions. The journey through metal mastery unveils more hidden truths...

Using the right filler materials is crucial, often dramatically impacting the final weld's strength and appearance. Welders who specialize in niche materials are increasingly sought after, spotlighting the growing specialization within the field. But the alchemical story of metals doesn’t end there...

These material advancements are making aerospace and automotive industries rethink their design standards, pushing the boundaries of what structures can do. The next chapter of this metallic evolution is just unfurling. But how did traditional welding evolve into hi-tech solutions?

While traditional stick welding still holds a place, evolved techniques like laser welding have taken center stage in contemporary manufacturing. The transition from sparks and flame to precision and focus is nothing short of extraordinary...

Laser welding, with its pinpoint accuracy, offers unparalleled control and speed, reducing post-weld finishing. This can decrease costs in production pipelines significantly. The laser landscape, however, offers more surprises...

The increased use of hybrid techniques that blend laser with traditional methods showcases the industry’s innovative spirit. This melding of old and new offers the best of both worlds—strength and precision. The metal-working future is now peppered with these advances. But what makes these contemporary methods so compelling?

Innovative methods are spurring collaboration between designers and engineers, fostering environments where creative solutions to traditional problems arise. Welding, while anchored in fiery roots, is entering its brightest age yet. But what lies next in welding machine maintenance?

Despite boasting advanced technology, welding machines require rigorous maintenance to function optimally. Neglect can lead to downtime that is costly. Maintenance practices are evolving—here’s what’s surprising...

Predictive maintenance technologies now alert operators before malfunctions, using data to extend machine life and ensure seamless operation. This proactive approach is minimizing unscheduled repairs. But proactive maintenance is only part of the transformation...

Regular calibration is crucial, yet often overlooked, potentially leading to welding errors and reduced equipment lifespan. It's an insurance policy for perfection. Uncovering these maintenance secrets reveals more than expected.

The drive towards maintenance excellence is crafting a narrative of high operational efficiency and enhanced equipment reliability. Industries embracing these practices are witnessing remarkable ROI and sustainability. So, what are the future trends to watch in welding technology?

The future of welding technology lies in innovation—from virtual reality training tools to nanowelding. These advancements bring both excitement and speculation. The journey starts here...

Virtual reality is transforming welding training, allowing new welders to practice in a risk-free environment, dramatically cutting learning time. This accessibility invites a broader demographic into the field. But the future beckons further...

Nanowelding involves manipulating particles at the atomic level, offering promises of new, astonishingly strong yet lightweight materials. The implications stretch from medicine to construction. This microscopic revolution is just the beginning.

Innovations in autonomous welding processes hold the potential to reshape industries fundamentally. As we dive deeper into these visions, welding evolves once again, leading us into an era of possibility that defies expectations. What is the parting wisdom from this welding odyssey?

The welding industry is not just a cornerstone of manufacturing; it's a dynamic force shaping the future of sustainable innovation and creativity. Today's revelations are paving tomorrow's paths, filled with shimmering possibilities and groundbreaking technologies. Share this with those curious minds around you - because the welding evolution has only just begun.